Sodium phosphate tribasic dodecahydrate in the dyeing and printing industry

Sodium phosphate tribasic dodecahydrate in the dyeing and printing industry

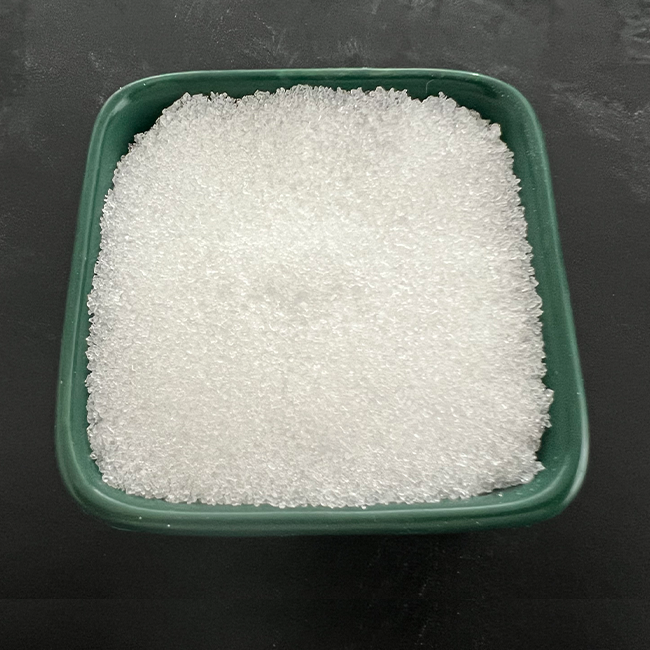

Sodium phosphate tribasic dodecahydrate (CAS 10101-89-0), as an important industrial chemical, plays an indispensable role in the printing and dyeing industry. It not only improves the efficiency and quality of the printing and dyeing process, but also enhances the aesthetics and durability of the final product. In this article, we will introduce in detail the specific applications of Sodium phosphate tribasic dodecahydrate in the printing and dyeing industry, and how these applications are close to our daily life.

1.Water quality softening, enhance the printing and dyeing effect

Water quality is a crucial factor in the printing and dyeing process. Calcium and magnesium ions in hard water will react with dyestuffs, resulting in dyestuffs precipitation, thus reducing the printing and dyeing effect.Sodium phosphate tribasic dodecahydrate, as a kind of high efficient water softener, can combine with calcium and magnesium ions in water to form insoluble phosphate precipitation, thus effectively removing these ions and softening the water quality.

In our daily life, the textiles we wear such as clothing, bedding and curtains, their colorfulness and pattern clarity are largely due to the softening of the water used for printing and dyeing by Sodium phosphate tribasic dodecahydrate. The softened water allows the dyes to penetrate more evenly into the fibers, improving the printing and dyeing results and making the colors of the clothing last longer and brighter.

2. Dyeing and color fixing: the magic weapon to enhance color fastness

Sodium phosphate tribasic dodecahydrate is also used as a color fixing agent to help the dyes fix better on the fibers during the dyeing and printing process to improve the dyeing fastness. During the dyeing process, Sodium phosphate tribasic dodecahydrate forms a stable bond with the dye molecules, reducing the possibility of the dye coming off during washing or use. This not only helps to maintain the vividness and durability of the color of the dyed products, but also prolongs the service life of the products.

For example, when we buy clothes, we often find that the color of some clothes becomes obviously faded after a few washes. However, the color of clothes treated with Sodium phosphate tribasic dodecahydrate remains as vivid as before even after many washes. This not only improves the aesthetics of the clothes, but also increases consumer satisfaction and loyalty.

3. Enhance the gloss and feel: meet the needs of high-grade textiles

The addition of Sodium phosphate tribasic dodecahydrate can also improve the smoothness of the fiber surface, so that the printed and dyed products have a better luster and feel. This role is particularly important in high-grade textiles, such as silk, cashmere and so on. These textiles not only require bright colors, but also require a soft feel and good gloss. the addition of Sodium phosphate tribasic dodecahydrate makes it possible to meet these requirements and improve the overall quality of the product.

In our daily life, we wear high-grade clothing, scarves and shawls, etc., whose gloss and feel are largely due to the treatment of Sodium phosphate tribasic dodecahydrate. These textiles not only give us a more elegant appearance, but also provide us with comfort and pleasure to the touch.

4. Auxiliary decontamination: providing a clean base for the printing and dyeing process

In the pre-treatment stage of printing and dyeing, Sodium phosphate tribasic dodecahydrate can also assist in removing oil and impurities from the surface of fabrics. Its slippery feel and certain emulsifying effect help to separate dirt from the fiber surface, providing a clean fiber surface for the subsequent printing and dyeing process. This not only improves printing and dyeing efficiency, but also enhances the quality of the final product.

For example, some of the clothes we wear require special decontamination treatments before printing and dyeing, and the addition of Sodium phosphate tribasic dodecahydrate makes these decontamination treatments more efficient and thorough, and provides a good foundation for the subsequent dyeing and printing processes.

5.Regulate the performance of printing and dyeing solution: ensure the stability of the printing and dyeing process

Sodium phosphate tribasic dodecahydrate can also be used as a buffer for printing and dyeing solution, regulating the pH of the printing and dyeing solution and maintaining the stability of the printing and dyeing solution. This is very important to ensure the smooth running of the printing and dyeing process and to improve the printing and dyeing efficiency. In the printing and dyeing industry, the stability of the dyeing solution is directly related to the quality of the final product, and the addition of Sodium phosphate tribasic dodecahydrate makes the dyeing solution always maintain the appropriate pH during the printing and dyeing process, which ensures the stability and controllability of the dyeing and printing process.

Sodium phosphate tribasic dodecahydrate has wide and important applications in the dyeing and printing industry. It not only improves the efficiency and quality of the printing and dyeing process, but also enhances the aesthetics and durability of the final product.

trisodium phosphate dodecahydrate uses

sodium phosphate tribasic dodecahydrate formula

does na3po4 dissolve in water

sodium phosphate dodecahydrate molar mass

trisodium phosphate reaction with water

is trisodium phosphate poisonous

tri sodium phosphate application

sodium phosphate dodecahydrate formula