Ammonium Dihydrogen Phosphate

Ammonium Dihydrogen Phosphate

In the global green agriculture and new energy industry booming today, efficient and environmentally friendly chemical raw materials have become an important cornerstone to promote industrial upgrading. Shandong Jiurunfa Chemical Technology Co., Ltd. with years of technical accumulation and innovative practice, has launched high purity Ammonium Dihydrogen Phosphate DAP CAS No. 7783-28-0, which injects new power for agriculture, food industry and new energy field with excellent quality and diversified application scenarios. This product not only carries the efficient nutrients of traditional phosphate fertilizers, but also shows its unique value in industrial innovation, becoming a reliable partner for customers to achieve the goal of sustainable development.

1, product characteristics: balanced nutrients, stable performance

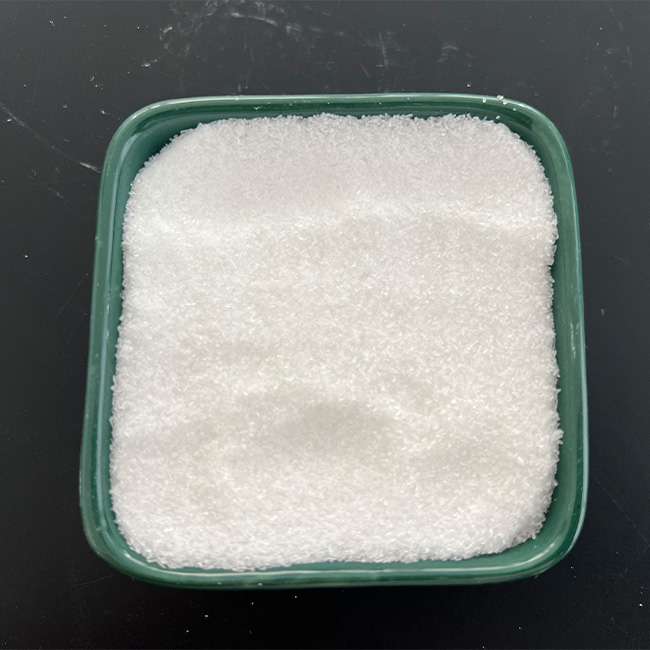

Ammonium Dihydrogen Phosphate (DAP), with the chemical formula (NH₄)₂HPO₄, is a kind of white crystalline or granular inorganic salt, which is easily soluble in water, and the aqueous solution is slightly alkaline (the pH value of 1% solution is about 7.5-8.5). Its molecule is rich in two key nutrients, nitrogen (18%) and phosphorus (46%), with balanced nutrient ratios, and is thermally stable, so that it can maintain a stable structure even under high-temperature environments. Jiurunfa Chemical adopts the international advanced production process to ensure that the product purity ≥ 99.5%, with very low impurity content (heavy metals ≤ 3ppm, chloride ≤ 0.005%), which can meet the needs of food grade, electronic grade and other high-precision applications.

2, agricultural field: the innovation power of efficient fertilizer

In agricultural production,Ammonium Dihydrogen Phosphate (DAP) has become one of the preferred fertilizers for modern precision agriculture due to its high phosphorus content and instant solubility characteristics. Compared with ordinary phosphate fertilizers, DAP dissolves faster and releases nutrients more intensively, which is especially suitable for rapid improvement of phosphorus-deficient soils. For example, in the corn planting test in the black soil area of Northeast China, the corn root development was significantly enhanced in the field using DAP as the base fertilizer, the grain fullness was increased by 22%, and the acre yield was increased by nearly 300 kilograms. In addition, DAP can also be compounded with urea, potash, made of water-soluble fertilizer or drip irrigation special fertilizer, to help facilities for agriculture to achieve the “reduction of efficiency”.

For soil acidification, DAP's slightly alkaline qualities can neutralize soil acidity and reduce aluminum ion poisoning, especially suitable for tea gardens and orchards in southern red soil areas. After the introduction of JRF DAP to an organic tea garden in Fujian, the soil pH was raised from 4.3 to 5.8, and the amino acid content of the tea increased by 15%, with the quality reaching the EU organic certification standard. The company also cooperated with agricultural research institutions to develop a slow-release DAP granules, through the coating technology to extend the fertilizer cycle, reduce the frequency of fertilizer application, to provide a more economical solution for large-scale planting.

3, the food industry and new energy: the infinite potential of cross-border applications

Ammonium Dihydrogen Phosphate(DAP) has shown unexpected value in the food processing field. As a food additive (E342ii), it is widely used as a bulking agent and fermentation aid in bakery products. For example, after a famous bread brand used DAP to replace traditional bulking agent, the fermentation time of dough was shortened by 20%, and the finished product had a larger volume and a softer texture, which was warmly received by the market. In addition, DAP can also be used as yeast nutrient in the brewing industry to promote the efficiency of alcohol fermentation. After the application of DAP by a brewing company, the fermentation cycle was reduced by 12% and the annual production capacity was increased by nearly 10,000 tons.

In the new energy field, DAP is becoming one of the key raw materials for lithium battery material preparation. Its high purity characteristics can be used to synthesize lithium iron phosphate (LiFePO₄) precursor, to ensure the electrochemical stability of the battery anode material. Jiurunfa Chemical has cooperated with many power battery enterprises to customize electronic grade DAP products, with sodium, potassium and other metal impurities controlled below 0.5ppm, to help customers improve the battery cycle life to more than 4,000 times, to meet the demand for long electric vehicle range. At the same time, DAP also has an emerging application in the photovoltaic industry - as a buffer component of silicon wafer cleaner, it can effectively remove surface impurities without damaging the crystal lattice structure, which helps to improve the efficiency of solar cells.

4, production process: technology-enabled, quality first

Jurongfa Chemical always regards technological innovation as its core competitiveness. Diammonium Hydrogen Phosphate (DAP) production adopts the integrated process of “neutralization-concentration-crystallization”, using food-grade phosphoric acid and high-purity liquid ammonia as raw materials, and ensuring the purity of the product and the homogeneity of the crystalline form through precise control of the reaction temperature and pH value. Centrifugal spray drying technology is introduced in the production process, so that the water content of the finished product is ≤0.1%, and the particles have excellent fluidity, which completely solves the problem of easy caking in the traditional process.

In order to meet the needs of different industries, the company also provides flexible product customization services. For example, for high-end electronic materials, the impurity ions are reduced to ppb level by multi-stage membrane filtration technology; for food additives, the aseptic production line is used for packaging, which meets the HACCP and FDA certification standards. The entire production line is monitored and controlled by DCS system, which ensures stable parameters and zero difference in quality for each batch of products.

di ammonium hydrogen phosphate

ammonium phosphate dibasic chemical

ammonium dibasic 7783 28

di ammonium phosphate reagent grade

ammonium phosphate dibasic reagent